Automated Decontamination

Discover the cutting-edge technology of Tekceleo’s modular automated decontamination nozzles. Our team of experts is dedicated to providing innovative solutions with advanced motion and aerosol generation technologies to achieve your goals more efficiently and accurately.

Our solutions are designed to improve productivity, efficiency, and reliability, ensuring that you can achieve your objectives with confidence.

Precision Technology

Precise Decontamination

Precision technology is essential for effective decontamination, and Tekceleo’s modular nozzle delivers just that. Our innovative solutions use aerosolized H2O2 (hydrogen peroxide) for automated decontamination, with a focus on precision and efficiency.

Our modular nozzle allows for easy and efficient decontamination, even in small or hard-to-reach areas. With our technology you can easily bring automated decontamination to your equipment.

Our team of experts is dedicated to providing the best possible service and support, so you can focus on what matters most – your work. Trust Tekceleo for precision technology and precise decontamination.

Your Partner for Innovation

At Tekceleo, we pride ourselves on delivering high-quality and innovative solutions that help our customers achieve their goals.

Our advanced aerosol generation, humidification and decontamination technologies are designed to improve efficiency, productivity, and reliability. Our team of experts provides full support throughout the entire process, from initial design and implementation to ongoing maintenance and troubleshooting.

We work closely with our customers to understand their unique needs and requirements, and we provide customized solutions that meet those needs. With Tekceleo, you can count on our expertise and dedication to help you achieve your goals faster and with greater accuracy.

Creating Easy Solutions for

Complex Problems

Bring Decontamination To The Edge

Micronice decontamination nebulizers use aerosolized hydrogen peroxide (VHP) to create a fine mist that fills a space and decontaminates every surface, even those that are difficult to reach.

This technology is highly effective at killing viruses, bacteria, spores and other pathogens, making it an ideal solution for medical facilities, laboratories, and other settings where cleanliness is critical. It has been proved to achieve EN 17-272 norm for airborne disinfection.

Our H2O2 nozzles are also electronically control, which means easy to plug to your PLC (PWM control method).

Highlights of our Decontamination Technology

Advanced Aerosol Generation technology for precise H2O2 decontamination

Modular Design for easy installation and Customization

Dedicated Engineering support for easy integration and technical assistance

Compatibility with a large range of Decontamination agents (hydrogen peroxide, peracetic acid...)

Electronically Controlled - High level of automation possible

High Efficiency : very low power consumption (<2W), little to no dead volume of biocide

Low Maintenance and high lifespan, minimizing downtime and expenses

No pressure nor temperature rise, adapted for very small volumes and sensible materials

Very small footprint and compact, making it easy to integrate in every environment

Our Technology Overview

An Amplified Vibrating Mesh Technology

Tekceleo’s Amplified Vibrating Mesh Technology relies on a piezoelectric transducer to make a micro-perforated mesh vibrates at ultrasonic frequency. When a liquid comes into contact with the membrane, it’s transformed into a cloud of precisely calibrated micro-droplets, with a monodispersed nebulization. This technology generates aerosols or sprays with very low power consumption, making it ideal for integration into modular devices, mobile equipment, miniature instruments, and handheld devices. The use of piezoelectric technology allows for very low response times, and the electronic control provides great flexibility of use. This gives our customers a competitive advantage in terms of reliability, precision, and energy efficiency.

TEKCELEO offers two main design of nebulizers, all of which allow precise, efficient and monodispersed atomization:

P&S 360 nebulizer systems, using a circulating fluidic system for easy integration in automatized processes.

P&S T45 nebulizer systems, using a gravity-fed mode for easy and handeld uses.

All of our systems use the same patented Micronice amplified vibrating mesh technology.

Technical Characteristics

Range of Droplet Sizes

Amplified Vibrating Mesh technology allows to play on different droplet sizes

05 µm droplet size

Nominal flowrate : 0,8 ml/min

08 µm droplet size

Nominal flowrate : 3 ml/min

12 µm droplet size

Nominal flowrate : 4,5 ml/min

20 µm droplet size

Nominal flowrate : 8 ml/min

50 µm droplet size

Nominal flowrate : 35 ml/min

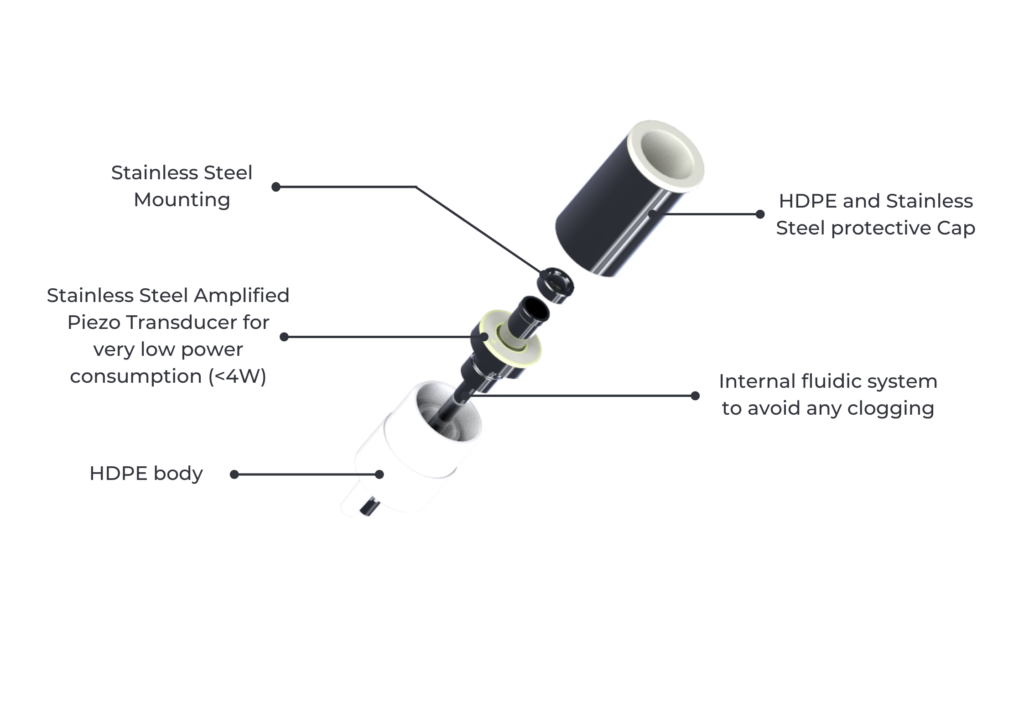

Mechanical Characteristics

Our nozzles are compact and easy to integrate in any devices

Light Weight : 40 grams

Materials

Metallic parts : SS316L and SS304 / Others: HDPE, pharma grade silicon

Diameter : 20 mm

Length

P&S T45 : 70 mm / P&S 360 : 56,5 mm

Long lifespan

Tested lifespan with RO water : >10 000 hours

Electronics and control

Our technology is electronically native and easy to control

Between 2 to 3 W per Nozzles

One Electronic controller can control up to 10 nebulizers

ECU available from x1 control to x10 control

Flowrate control by 1% increment with PWM signals

PWM interface 3.3V on BNC connector of ECU

Easy to integrate with your own PLC

12V or 24 V entry, contact us to know more about integration with PLC

Fluidic

Systems

Circulating Fluidic System or directly on the tap with a drain

P&S T45 Design : 10 ml integrated tank

10 ml integrated tank / Gravity-fed design that can only sustain nebulization up to 45° from the ground

P&S 360 Design

External reservoir > 500 mL Circulating fluidic system with peristaltic pump Compatible tube : 3mmx5mm

Pressure characteristics

No pressure in the fluidic system Max pressure to be put on the mesh : 0,1 bar

Temperature range

No need to heat the system. Temperature range from -20°C to 80°C for standard version. High temperature version on demand.

Write Us

TEKCELEO has created a highly innovative team with a recognized know-how in mechatronics and piezoelectric technology. The company is composed of a multidisciplinary team of engineers and physicists who have all the necessary tools to integrate the various technologies composing a product: mechanics, plastics, thermics, electronics, embedded software…

TEKCELEO has an electronics laboratory with scientific analysis and control equipment, latest generation design and simulation software and a mechanical prototyping and production workshop.