What is an automated decontamination system and why use it ?

Automated decontamination process aim to reduce drastically micro-organism presence and activity in a surface without human presence or even intervention. Unlike classical disinfection, automated decontamination aim to remove contamination in all part of a given volume.

Several system are possible for this process :

- Vaporized Hydrogen Peroxide (VHP). These system use H2O2 at high temperature to produce a gas that will saturate the volume. Very effective but with lot of restraint : temperature rise, corrosion, long ventilation cycles.

- Aerosolized Hydrogen Peroxide (aHP). In this case we are talking about chemical misting of biocide. Most of the time H2O2 is aerosolized. Tekceleo’s Micronice technology is a new aHP solution. aHP has the advantage to let the volume remain at ambient temperature and is easier to set than VHP.

- Ultraviolet C radiation (UVC). UVC system main problem is that some of the volume can be protected from the radiation (restraint of line of sight and shade or due to a less precise cleaning on certain zones) and result in remaining contamination.

These system aim to improve biological safety of personnel, environmental hygiene and to simplify and secure processes involving handling of micro-organisms or contaminating components.

Some example of automated decontamination benefits depending on the industry :

- Pharmaceutical industry : increase in the protection of the personnel while increasing the productivity of the production.

- Food industry : drastically reduce risks of contamination without sacrificing productivity.

- Hospitals : drastically reduce nosocomial diseases occurrence for patients.

Which equipment can be concerned ?

Automated decontamination can be applied to any closed volume. As a result a wide range of application is possible. Its main advantage is to provide a reliable, automated and effective process to reduce risk of contamination.

Automated decontamination system are widely used in pharma industry, for whole room disinfection but also inside equipment such as :

- Isolators (regulatory obligation for most of them)

- Biosafety Cabinet

- Pass-box

- Airlock

These equipment can also be used in hospitals or veterinary environment.

For the food industry, automated decontamination system can be used for closed volume such as tanks or conditioning areas.

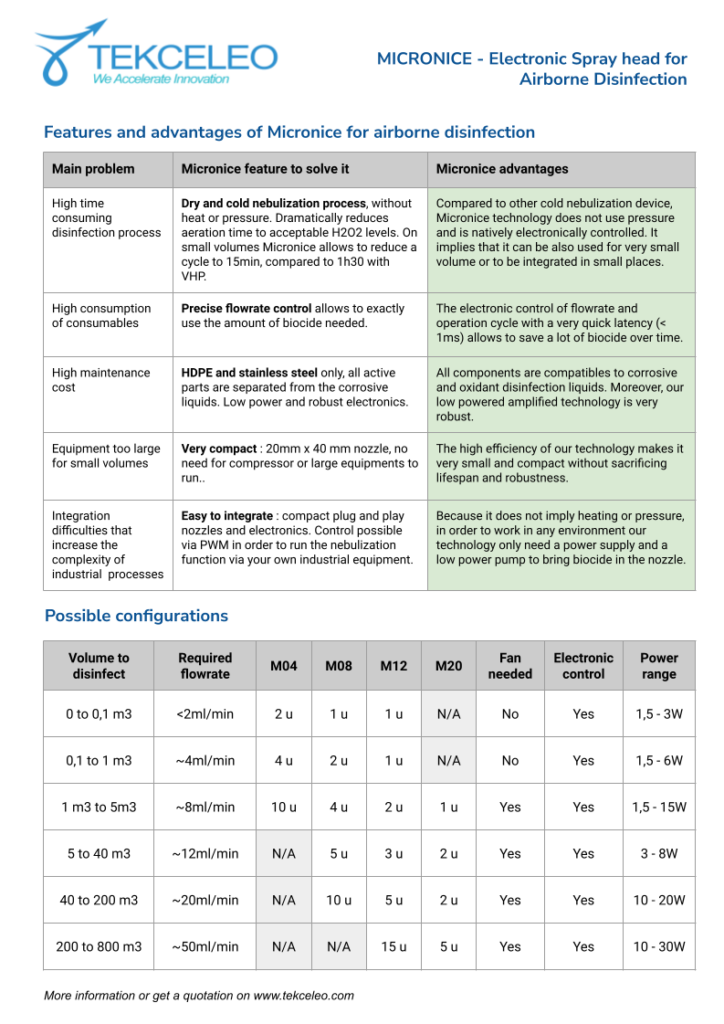

Regarding Tekceleo’s Micronice solution, our wide range of nozzle, simplicity to use and low footprint allows for a lot of different configuration and customization depending on your need. You can see the key parameters in our brochure at the following link : https://www.tekceleo.com/wp-content/uploads/2023/04/Tekceleo_Catalog-PS-2022-2023.pdf

How to use Tekceleo’s Micronice technology for automated decontamination ?

Micronice technology is perfectly suited for automated decontamination of small volume. Its ability to be easily integrated (low footprint) and to nebulize very small aerosol without any rise in temperature or pressure is perfect for volume inferior to 1 m3. Nevertheless, as mentioned in the table above, Tekceleo’s nozzle can be integrated in all kind of automated decontamination system, even for very large volume.

To integrate our technology in your device is pretty simple :

- You need to put the spray face of the nozzle in the volume to decontaminate;

- Connect the nozzle to its controller and to a fluidic system (peristaltic pump);

- Set the pump ;

- Set your spraying cycle and target flowrate;

- Launch the nozzle via the controller (can be remotely controlled);

This simple set up, composed of our P&S 360 standalone kit, is already in use for Biosafety Cabinet and isolators decontamination and has passed the EN 12272:2020 standard (with H2O2 8%, H2O2 30% and H2O2 7% + Peracetic acid 0,5%) . You can see more regarding this set up in our related video : https://www.youtube.com/watch?v=k3s54O8nDMM

For volume superior to 1 m3 or to achieve higher decontamination result it is recommended to add a fan to the system. In the right configuration, our technology is able to reach log 5 to 6 in decontamination for bacteria, fungi, spores and viruses.

With our simple, modulable and customizable system we aim to provide easy solution to all pharma, medical and veterinary equipment manufacturer, as well as decontamination expert. We provide support to integration of our system and facilitate your process to add value to your equipment. Thanks to our technology you can easily add an embedded automated decontamination process to your equipment or volume.

Conclusion

An automated decontamination process is more and more a must-have or a high added value for equipment of several industries :

- Pharma

- Medical

- Veterinary

- Food

In order to provide a simple and efficient solution for automated decontamination in small volume, work enclosures or within automated production processes Tekceleo’s Micronice technology is very effective.

Our amplified vibrating mesh technology has a very low footprint that allows for easy integration in every volume and equipment possible and is very simple to use, as it is electronically controlled and is based on a very gentle nebulization process. Our nozzle is compatible to all biocide and allows for “set and forget” set up, with very little to no maintenance needed.

With the use of our technology, you can easily add value to your equipment or easily provide decontamination services. Contact us for more information !