Redifining Small Volume Sterilization for Pharma Industry

Elevating Precision and Efficiency with Amplified Vibrating Mesh Technology. In the realm of pharmaceuticals, achieving precision and efficiency in small volume sterilization is paramount. This vital process ensures the safety and integrity of pharmaceutical products, making it a cornerstone of pharmaceutical manufacturing.

Enter Tekceleo’s groundbreaking Micronice aerosol generator, driven by amplified vibrating mesh technology. It’s poised to revolutionize small volume sterilization, offering unprecedented precision and efficiency to the pharmaceutical industry.

The Critical Role of Small Volume Sterilization

Small volume sterilization is a mission-critical step in pharmaceutical manufacturing. Its primary goal is to eliminate or substantially reduce microbial contamination from pharmaceutical solutions, suspensions, and small-volume containers. This process is instrumental in safeguarding patient health and upholding the quality of pharmaceutical products. The importance of small volume sterilization cannot be overstated:

- Patient Safety: Sterilization ensures that pharmaceutical products are entirely free from harmful microorganisms, significantly reducing the risk of infections and adverse reactions in patients.

- Drug Stability: Sterile products enjoy extended shelf lives, preserving the potency and effectiveness of pharmaceutical drugs over time.

- Regulatory Compliance: Regulatory agencies enforce strict sterility standards to guarantee product quality and safety in pharmaceuticals.

- Research and Development: Small volume sterilization is indispensable for the development of new drugs and formulations, enabling accurate testing and research.

- Quality Assurance: Sterilization is a fundamental part of quality control, preventing contamination during the production of pharmaceuticals.

- Consistency: Achieving consistent sterilization is essential for maintaining product quality and compliance with industry regulations.

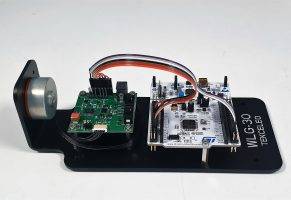

Dive into our Amplified Vibrating Mesh

Nebulizers Range

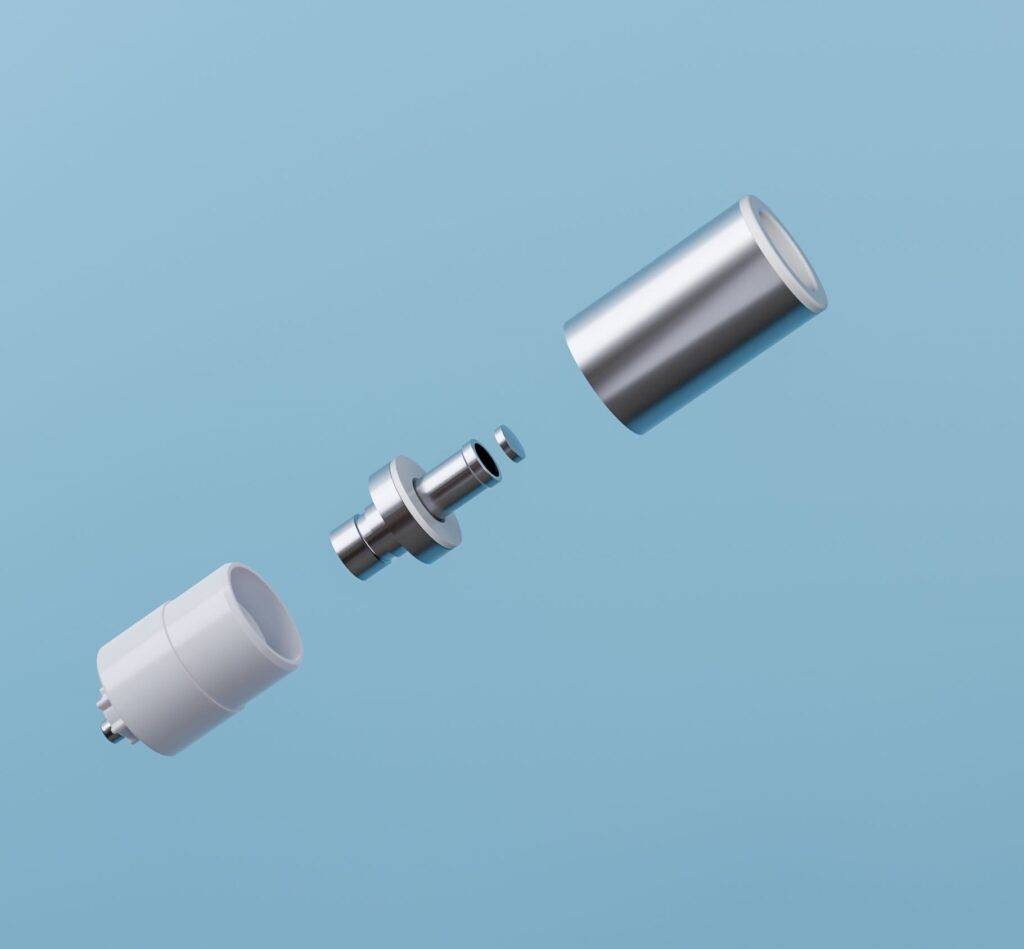

The Power of Micronice Decontamination Nozzles

Unleash Your Small Volume Sterilization Potential.

- Amplified Vibrating Mesh Technology: At the core of Micronice’s exceptional performance lies amplified vibrating mesh technology. This innovation ensures consistent and uniform dispersion of sterilizing agents, setting new standards for small volume sterilization. With Micronice, you can achieve unparalleled precision and reliability.

- Customizable Parameters: Micronice offers a broad range of adjustable parameters, allowing you to tailor the sterilization process to your specific requirements. Fine-tune variables such as sterilant concentration, exposure time, and temperature to meet your pharmaceutical formulation needs.

- Enhanced Efficiency: Experience significant time and resource savings with Micronice’s remarkable efficiency. Its design minimizes material waste, offering a cost-effective solution for small volume sterilization.

- Reliability and Consistency: Trust Micronice for consistent results batch after batch, reducing the risk of microbial contamination and ensuring compliance with pharmaceutical industry standards.

Enhancing Pharmaceutical Safety

One of Micronice’s standout features is its ability to achieve small volume sterilization with unmatched precision. In an industry where patient safety is paramount, Micronice’s precision is a game-changer.

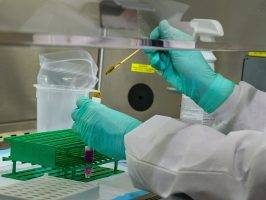

Sterilization of Pharmaceutical premises and work equipment is a safety norms for both patients and technical operator in pharma processing. The Pharma industrials need to comply with GMP (Good Manufacturing Practices) such as Annex 1 – Manufacturing of Sterile Products from the European Commission.

Tekceleo Nebulization technology allows industrial to easily comply with such exigences and enhance pharmaceutical safety for all stakeholders.

Elevating Small Volume Sterilization

Precision, Reliability, and Efficiency Redefined. Tekceleo’s Micronice aerosol generator stands as a testament to our commitment to advancing pharmaceutical manufacturing. By harnessing the potential of amplified vibrating mesh technology, we’ve transformed small volume sterilization into a highly controlled, precise, and efficient process.

Ensuring Pharmaceutical Products Integrity

Small volume sterilization allows for the precise elimination of microbial contaminants from pharmaceutical solutions and suspensions. This level of control empowers pharmaceutical companies to:

- Enhance Patient Safety: Ensure pharmaceutical products are free from harmful microorganisms, minimizing the risk of infections and adverse reactions in patients.

- Extend Shelf Life: Sterilized products have longer shelf lives, reducing product wastage and improving cost-efficiency.

- Regulatory Compliance: Comply with stringent regulatory standards for sterility, ensuring product quality and safety.

- Facilitate Research and Development: Small volume sterilization is essential for developing and testing new pharmaceutical formulations, supporting accurate research and development processes.

- Quality Assurance: Maintain product quality and consistency by preventing contamination during production.

Easy, Automated and GMP Compliant

Our cutting-edge technology simplifies the sterilization process, making it effortless and precise. With Micronice, you can automate critical steps, ensuring consistency and reliability in your pharmaceutical manufacturing. Plus, rest easy knowing that our system adheres to Good Manufacturing Practices (GMP), meeting the stringent quality and safety standards demanded by the pharmaceutical industry. Discover the convenience of Micronice and elevate your small volume sterilization processes to a new level of efficiency and compliance.

Micronice native electronic control and great precision allows for direct integration and automation. Its ability to spray H2O2 at high concentration for very long time periode decrease risks and secure operation for GMP manufacturers.

Implementing Automated Decontamination

In the dynamic landscape of pharmaceutical manufacturing, efficiency, precision, and compliance are paramount. Tekceleo’s Micronice aerosol generator stands as a testament to our commitment to empowering the industry. One of its exceptional features lies in its ability to seamlessly integrate automated sterilization routines, revolutionizing small volume sterilization processes.

By implementing Tekceleo nozzles within your automated decontamination system, you not only enhance efficiency but also maintain the highest standards of cleanliness and compliance in pharmaceutical manufacturing.

Precision and Compliance

Micronice technology is designed to put precision and compliance at the forefront of your pharmaceutical manufacturing operations. With its user-friendly interface and customizable parameters, you have the power to effortlessly create automated sterilization routines tailored to your specific needs. This not only streamlines your operations but also ensures consistency and adherence to Good Manufacturing Practices (GMP). Experience the ease of Micronice technology and elevate your pharmaceutical manufacturing to new heights of efficiency and compliance.

Empowering Pharmaceutical Manufacturing

Here’s a brief guide on how to implement Tekceleo nozzles to establish a highly efficient automated decontamination solution:

Nozzle Selection: Begin by selecting the appropriate Tekceleo nozzle for your decontamination requirements.

System Integration: Integrate the chosen Tekceleo nozzle into your existing decontamination setup or design a new system. The nozzles can be easily integrated into enclosures, chambers, or controlled environments.

Parameter Configuration: Customize settings such as flow rate, particle size distribution, and exposure time to achieve optimal decontamination efficiency.

Testing and Validation: Before deploying the automated decontamination system for routine use, conduct thorough testing and validation procedures.

Routine Operation: Once validated, your automated decontamination system is ready for routine operation.

Join the Future of Pharmaceutical Sterilization

Contact Us for a Consultation

Are you ready to experience the transformative technology of Micronice for small volume sterilization? Contact our team of experts today for a comprehensive consultation and discover how amplified vibrating mesh technology can elevate your pharmaceutical manufacturing processes. With Tekceleo’s Micronice aerosol generator, precision, reliability, and efficiency are within your reach.

Our Articles

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

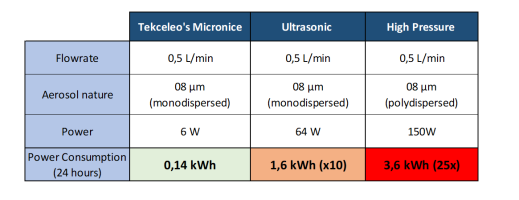

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…