Why producing calibrated droplets for aerosol generation ?

Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant.

By ensuring a monodispersed droplet size with a high level of dispersion constancy an aerosol generator help to calibrate instrument or to understand key variable in research.

For example, droplet generator help to calibrate particle measurement devices, or to study a specific aerosol with all other things being equal.

When droplets are produced with consistency in there size dispersion and with very good reproducibility they can be applied to a wide range of applications :

- Filter testing ;

- Particle measurement calibration ;

- Development of new filter ;

- Inhalation test, in-vivo aerosol testing ;

- Surgical mask test ;

- Microbiological studies ;

- Aerosol study ;

- Precise coating ;

- Detector testing ;

- Cleanroom and safety cabinet validation.

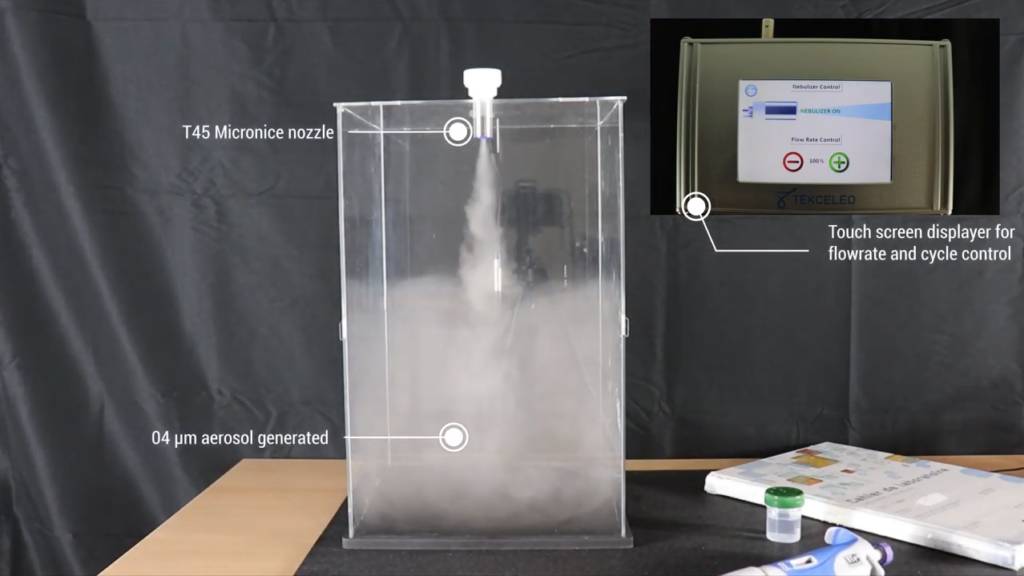

Tekceleo’s P&S T45 : aerosol generation made easy

With our T45 Aerosol Generator, we provide an easy solution for multipurpose aerosol generation :

- Monodispersed droplet generation, with standard droplet size available from 04 µm to 50 µm ;

- Adaptable flowrate, with very low latency control (< 1 ms) and possibility to control aerosol generation with 1% increment ;

- Aerosol generation from 100 µL/min to 40 ml/min ;

- Easy to fill and reload 10 mL integrated tank ;

- No dead volume, 100% of the liquid is aerosolized ;

- Very robust and resistant : can generate aerosol at temperature up to 200 °C ;

The T45 aerosol generator is very ergonomic and easy to use. Everyone can use it to generate very precise and calibrated aerosol. It works without any noise, rise in temperature or complex handling :

- Just fill and close the tank ;

- Plug the T45 aerosol generator to its controller ;

- Set the flowrate and start the aerosol generation.

How it works ?

Tekceleo developed the Micronice© technology based on an amplified vibrating mesh principles. Our aerosol generator use the piezo principle to make a microperforated membrane vibrates at ultrasonic frequencies.

These vibration create a movement of the membrane on the liquid itself that create the atomization process. This process is generated by very small and precise movement and with a well-calibrated membrane, which allows for very precise aerosol generation. Our technological principle has several advantages :

- Lot of room for customization, as the membrane (mesh) can be custom-made.

- Natively electronically controlled, making it very simple to control every aspect of the aerosol generation (very low latency) ;

- No noise, heat generation or alteration of the liquid. Liquid is gently extruded by the movement of the membrane and not generated by any pressurized or heating principle.

- Very compact : piezo technology allows for miniaturization.

On-demand development for specific use cases

As a result, our technology can be customized depending on the need of the client. The main aspect that can be made on demand is the vibrating mesh part. Customization can adapt :

- Droplet size distribution : be centered on the particle size you want ;

- Flowrate : generate the flowrate you need, even for micro doses (µL range) ;

- Supported liquid and temperature : material changes are possible in order to sustain extreme aerosol generation ;

Currently, Tekceleo has made custom T45 aerosol generator for challenging use cases :

- Aerosolization of molten salt (> 200°C) for nuclear studies ;

- Aerosolization of photo resistant coating liquid at 200 °C ;

- Aerosolization of coal particles with very precise distribution ;