Electronic Nebulizers

Discover our Micronice amplified vibrating mesh technology. Our liquid atomizers, nebulizers and aerosol generators provide the perfect solution for precise and efficient aerosol generation. Our design is modular and simple, while maintaining a high degree of robustness and accuracy.

If you need to find solutions for your pharma process, microbiology, relative humidity control, aeroponics or other industries requiring aerosol technology, you’ll understand the advantages of our Micronice technology. Contact us to learn more about how it can benefit your application.

Know more about our Mesh Nebulizers

Based on a patented amplified vibrating mesh technology coupled with intelligent design, Tekceleo’s Micronice© nebulizers are among the most efficient on the market in terms of flowrate to size ratio, latency, precision and power efficiency.

Our design allow to use the precision and electronic drive of vibrating mesh nebulizer while drastically improving robustness and efficiency. Our technology can be use for very severe and strict environment and backgrounds.

Tekceleo has developed two different design, depending on the use :

- P&S T45 Design, simple to use with a 10 mL integrated tank. It is mostly aimed at researcher or sampling studies. Easy to fill, wash and refill, its compact and user friendly design allows you to test all different droplet sizes and liquids.

- P&S 360 Design, designed to allow optimal liquid circulation, it can be used in an independent fluidic system. Perfect design for continuous use, with one or more nozzles in series. The P&S 360 has been designed for precise use in automation.

In any case, our range of nebulizers is made to bring you precision and reliability in your work. Do not hesitate to consult our catalog or to contact us!

Main Advantages of our vibrating Mesh Technology

Tekceleo’s Micronice© technology offers numerous advantages over traditional aerosol technology, including high precision, reliability, and efficiency.

Our aerosol generators can generate aerosols from a wide range of liquid types, including suspensions and solutions, and are ideal for applications requiring precise droplet size control. Our atomization technology is used in Decontamination, precise Relative Humidity control, Micrometric Coating, and other applications requiring aerosol technology. Its superior performance and reliability makes it a popular choice from microbiology research to high-precision sectors, such as pharma industry.

Tekceleo can also offer customization services, allowing to adapt the Micronice technology to the needs of its customers. Contact us so that we can start working on your project and application !

Medical

Pharma

Industrial Automation

Aerospace

Our Articles

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

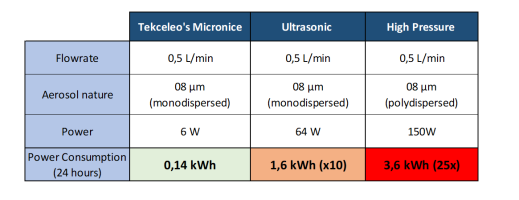

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…

Highlights of Micronice Amplified Mesh Nebulizer

High precision in flowrate control (up to 10µL.min steps)

Up to pharma and medical standards

Very high efficiency (<2W per nozzle)

High reliability (>5 000 hours)

High repeatability of process

No dead volume in operation

Wide liquid compatibility

Easy to control and to integrate in your automated process

No pressure nor heating to handle

Our technology Overview

An Amplified Vibrating Mesh Technology

Our Amplified Vibrating Mesh Technology use a piezoelectric transducer to make a micro-perforated mesh (membrane) vibrates at ultrasonic frequency. Whenever a liquid (solution, formulation, suspension) is in contact with the vibrating membrane, it is “extruded” into a cloud of micro-droplets on the other side of the membrane through micro-perforations. Generating a mist or spray through micron-sized holes allows the droplet size to be precisely calibrated with a very low-variance Gaussian distribution (this is called monodispersed nebulization). As a matter of physics, the aerosol or spray is not generated by any pressure inside the nebulizer nozzle. There is no relationship between droplet size and the liquid’s nozzle exit velocity. More precisely, the aerosol’s exit velocity is almost zero.

This is why this type of nebulization, when amplified piezoelectrically, generates aerosols or sprays with very low power consumption. Such an advantage makes this technology suitable for integration into modular devices (Set & Forget), mobile or portable equipment (disinfection robots), miniature instruments, and handheld devices. The electronic control of these nebulizers allows for great flexibility of use. The very low inertia of the liquid leads to very low response times (a few milliseconds). Combining these two properties and the very low power consumption (2W/nozzle) gives our customers critical, lasting competitive advantages.

TEKCELEO offers two main design of nebulizers, all of which allow precise, efficient and monodispersed atomization:

P&S T45 nebulizer systems, using a gravity-fed mode for easy and handeld uses.

P&S 360 nebulizer systems, using a circulating fluidic system for easy integration in automatized processes.

All of our systems use the same patented Micronice amplified vibrating mesh technology.

Some Examples and Applications

Liquid Aerosol Generator for microbiological studies : precise spraying of microorganisms, samples testing...

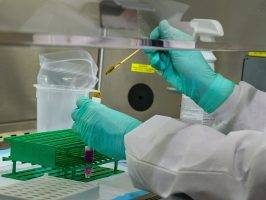

Decontamination : precise and repeatable aerosolization of H2O2 for automated decontamination of equipments such as BSC, isolators, etc.

Relative Humidity control : closed loop humidity control, with automated and precise spraying to remain close to saturation without condensation.

Food Preservation : precise humidifcation of fresh food products to avoid loss and ensure efficient conservation over time.

Aeroponics and Controlled Environment Agriculture : precise relative humidity control, as well as spraying nutrients onto the roots of plants.

Precise Coating for industry : automated aerosolization of coating liquid for 3D printing processes, microelectronics, textile industry...

Technical Characteristics of our Mesh Nebulizers

Range of Droplet Sizes

Amplified Vibrating Mesh technology allows to play on different droplet sizes

05 µm droplet size

Nominal flowrate : 0,8 ml/min

08 µm droplet size

Nominal flowrate : 3 ml/min

12 µm droplet size

Nominal flowrate : 4,5 ml/min

20 µm droplet size

Nominal flowrate : 8 ml/min

50 µm droplet size

Nominal flowrate : 35 ml/min

Mechanical Characteristics

Our nozzles are compact and easy to integrate in any devices

Light weight : 40 grams

Materials

Metallic parts : SS316L and SS304 / Others: HDPE, pharma grade silicon

Diameter : 20 mm

Length

P&S T45 : 70 mm / P&S 360 : 56,5 mm

Long lifespan

Tested lifespan with RO water : >10 000 hours

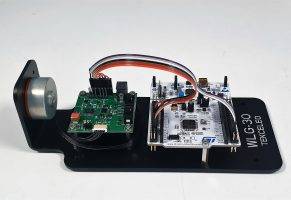

Electronics and control

Our technology is electronically native and easy to control

Between 2 to 3 W per Nozzles

One Electronic controller can control up to 10 nebulizers

ECU available from x1 control to x10 control

Flowrate control by 1% increment with PWM signals

PWM interface 3.3V on BNC connector of ECU

Easy to integrate with your own PLC

12V or 24 V entry, contact us to know more about integration with PLC

Fluidic

Systems

Needed fluidic systems depend on the design choosen : T45 or 360

P&S T45 Design : 10 ml integrated tank

10 ml integrated tank / Gravity-fed design that can only sustain nebulization up to 45° from the ground

P&S 360 Design

External reservoir > 500 mL Circulating fluidic system with peristaltic pump Compatible tube : 3mmx5mm

Pressure characteristics

No pressure in the fluidic system Max pressure to be put on the mesh : 0,1 bar

Temperature range

No need to heat the system. Temperature range from -20°C to 80°C for standard version. High temperature version on demand.