Humidification for Food Preservation

Cultivating freshness and extending the lifespan of perishables, humidification plays a pivotal role in food preservation. Welcome to our dedicated page focused on humidification for food preservation.

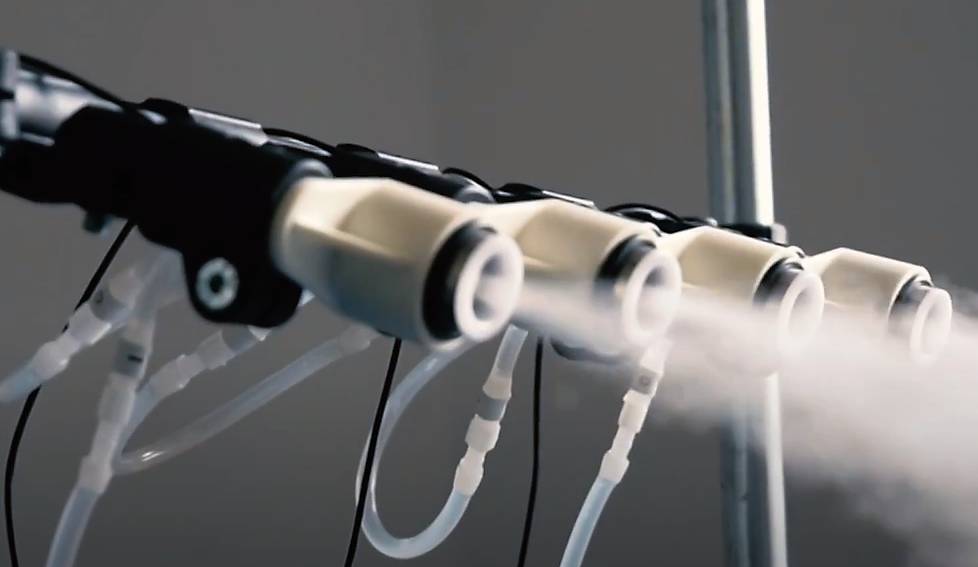

Here at Tekceleo, we delivered our best efficient design for an active nebulization nozzle that helps industrials to control environment easily with less resources and complexity. Explore how our advanced humidification systems redefine freshness, ensuring your customer’s products retain their peak flavor and texture.

Ensure Freshness and Quality

Tekceleo’s humidifying systems can be used to design foodstuff preservation systems, helping you to ensure freshness and quality are maintained at optimal levels.

Our technology stands out for its reliability and precision in creating the ideal humidity environment necessary for preserving various food items.

By controlling humidity levels with precision, it effectively prevents moisture loss and extend the shelf life of perishable goods. Whether it’s preserving the texture of fruits and vegetables or enhancing the flavor profile of delicate baked goods, our systems offer consistent performance and reliability. Haut du formulaire

Understanding the Role of Humidification

Understanding the role of humidification in food preservation is essential for ensuring the quality and longevity of perishable items. Tekceleo’s humidifying systems can play a pivotal role in this process by creating and maintaining the optimal humidity levels required for food storage.

By controlling moisture levels with very high precision, our systems help prevent dehydration and maintain the freshness of fruits, vegetables, meats, and other food products.

Great precision and non-wetting droplet size allows for humidification even in complex situation : small shelves, cold room, etc. Additionally, this precision means no condensation, and proper humidity regulation can inhibit the growth of mold and bacteria, further extending the shelf life of perishable items.

With Tekceleo’s expertise and technology you can design a great system to help your customer enhance their food preservation practices and ensure that their products reach consumers in the best possible condition.Haut du formulaire

Technology Enhancing

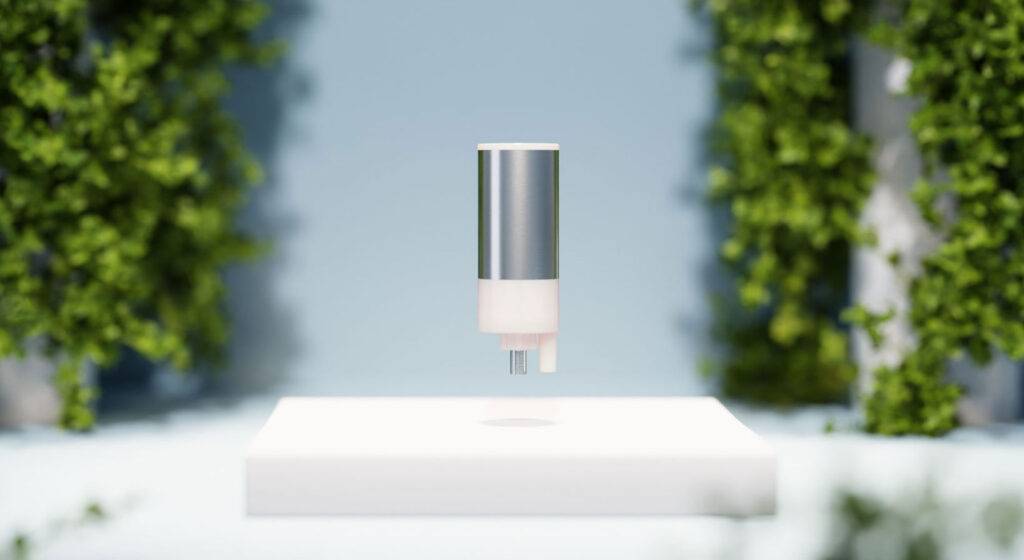

Foodstuff Life

Micronice offers non-wetting cold fogging system, with a wide variety of droplet size available : 05 µm, 08 µm, 12 µm, 20 µm. It is a modular technology, meaning you can play on how to place nozzles to have an optimal humidification of your volume and or food counter. Small droplets size also mean fast evaporation, creating an additional cooling effect in addition to its impact on humidity.

It is an electronically controlled technology, which allows for precise humidification and very low time response (< 10 ms). With Micronice, you can reach high humidity that prohibits transpiration and extends product shelf life, without any risk of condensation happening. This electronic control is also great if you want to couple our humidifying technology with humidity sensors in order to have a perfect humidity control.

Our technology can be used without any water reservoir, preventing any bacteria or viruses contamination of the water. As a result, maintenance and operation cost are reduced to a minimum. Micronice nozzle has also a very long lifespan when used with water, they have been extensively tested for more than 3 years of continuous operation without any breakage or problems.

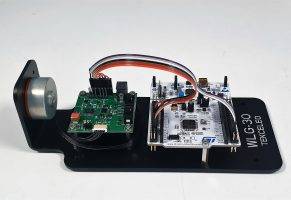

Secret Behind our Humidification Nozzle

Our Amplified Vibrating Mesh Technology use a piezoelectric transducer to make a micro-perforated mesh (membrane) vibrates at ultrasonic frequency. Whenever a liquid (solution, formulation, suspension) is in contact with the vibrating membrane, it is “extruded” into a cloud of micro-droplets on the other side of the membrane through micro-perforations.

As a matter of physics, the aerosol or spray is not generated by any pressure inside the nebulizer nozzle. As a result, our technology does not use any violent or restraining physical property to create a fog, making it very compact, robust and energy efficient !

Most Resources Efficient Technology

Efficiency is what sets our Humidification technology apart. Micronice vibrating mesh technology is unique and has the best efficiency to size ratio, with great volume, an energy efficiency that is better than a LED lighting and a very low water consumption.

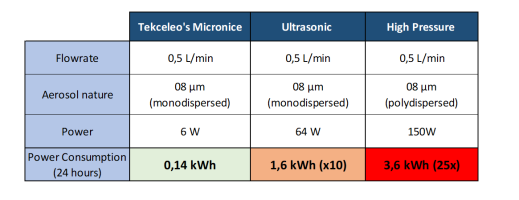

If we compare a system using Micronice technology to a system using ultrasonic fogging or usual misting technology :

- It uses 60% less water than a standard misting system

- It uses 12Wh/L compared to 250Wh/L for an ultrasonic unit

- Its long lifespan means less need to replace part

- Small footprint of the nozzle and system, as well as direct nebulization, which means less parts, less installation time and less risk of breakage and/or contamination. For example, our technology does not need any blower or complex control system.

As a result, choosing Micronice vibrating mesh technology for your humidification systems is the best resources-efficient choice you can make. Which means a better use of resources and less operational expenses during the life of the product.

If you want to use our technology and start an integration process, do not hesitate to contact us ! We provide a free engineering support.

Implement Micronice

Humidification Technology

Micronice technology can be implemented in various application, it is well suited for public spaces (quiet operation), but also for complex volume humidification (cold room, small spaces…).

In order to integrate our technology in your solution and adapt it to your use case, the main elements you need to take into account are :

- Dimensioning your humidification needs : what is the maximum water volume per minute you’ll need to inject in your air ?

- Set a water filtration system, which can be very easy with simple Reverse Osmosis systems

- Integrate the Nozzle(s) : you just need to fit a 20mm tube in your volume, for more advice on mechanical integration you can check our integration guide

- Plug nozzle to the controller : very easy, you can also use cable extension if you want to deport the electronic control.

- Set the fluidic system : either you’re using a pump or just directly on tap water, you simply need to plug the nozzle to the water input in series with flexible tubing. You can check our fluidic schematics on our integration guide or user guide.

- Set your control cycles : it is easy with a timer on ON/OFF cycle to set your time of operation. You can also directly control the flowrate of the nozzle or make a closed loop on a humidity sensor using our PWM flowrate control on the electronic controller.

Developping your Solution Using Micronice Nebulizers

Our innovative humidification technology provides precise and reliable humidity control in a user-friendly and modular design. Our advanced technology ensure that the humidity level is accurately maintained with minimal maintenance required.

Our modular design allows for easy installation and customization to meet your specific needs, making it the perfect solution for food preservation, controlled environment agriculture, research laboratories, manufacturing facilities, and other environments where precise humidity control is essential.

With our humidification technology, you can achieve consistent product quality, maintain a controlled environment, and achieve accurate and reliable results.

Embrace the Future of Humidification

If you’re interested in developing new solution for your food preservation products range, Tekceleo’s technologies is a great asset.

Whether you’re in need to develop something more efficient to improve your CSR and resource consumption or want to revolutionize environment control in your field with a more compact and precise technology, Micronice is a good fit.

Our engineering team offers free support for every customer which wants to use our technology, from first evaluation to industrialization. feel free to contact us !

Our Articles

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…