Most Efficent Humidifying Systems

Step into the world of advanced humidifying systems with Tekceleo. With precision engineering and innovative technology, we developed nebulization technologies that can help you crafting cutting-edge solution for Humidity Control.

From industrial applications to commercial spaces, discover how Tekceleo’s OEM expertise help manufacturers to developed products and solution that ensure optimal humidity levels, enhancing comfort and productivity worldwide.

Why Humidification ?

Humidification plays a crucial role in maintaining a healthy and controlled indoor environment, particularly in commercial and industrial settings. Proper humidity levels are essential for ensuring the well-being of employees, protecting equipment, and preserving product quality.

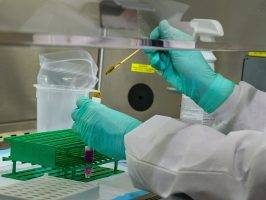

- Product Quality and Integrity: In sectors such as pharmaceuticals, food processing, and manufacturing, strict humidity control is essential to preserve the quality and integrity of products. Fluctuations in humidity levels can lead to degradation, spoilage, or changes in physical properties, affecting product efficacy and consumer safety.

- Process Control and Efficiency: Many industrial processes rely on specific humidity levels to ensure optimal operation and efficiency. Deviations from the desired humidity range can disrupt processes, leading to production delays, waste, and increased energy consumption. Precise humidification rate control helps maintain consistency and stability in manufacturing processes, resulting in higher productivity and lower operational costs.

- Regulatory Compliance: Certain industries, such as healthcare, pharmaceuticals, and electronics manufacturing, are subject to strict regulations governing environmental conditions, including humidity levels. Compliance with these regulations is essential to ensure product quality, safety, and regulatory approval. Precise control over the humidification rate helps businesses meet regulatory requirements and maintain compliance with industry standards.

Overall, the humidification rate is critical in various cases where maintaining specific humidity levels is essential for product quality, process control, occupant health, equipment performance, and regulatory compliance. Businesses must invest in reliable humidification systems capable of accurately controlling humidity levels to meet their operational and environmental requirements.

Cutting-Edge Ultrasonic Technology

Tekceleo’s technology is a new cutting-edge approach to humidification methods. While main existing solutions uses either evaporative, high-pressure or steam method, Tekceleo’s Micronice technology is using a unique piezoelectric ultrasonic approach.

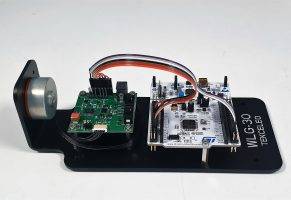

Our technology is using vibrating membrane to create calibrated droplets with very high efficiency. The nozzle is active : it nebulize directly every water in the nozzle when its powered. Which means Micronice systems are very simple : nozzles and controllers are enough. No need for complex centralized systems or pressure and temperature control.

Highly Resources Efficient

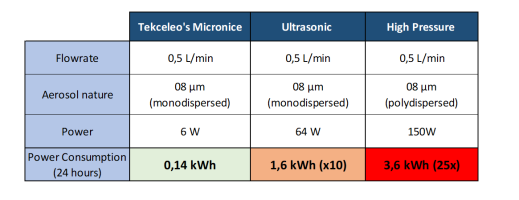

- Energy Efficiency : Micronice systems have the highest efficiency for humidification method, for example for a 0,5L/h water flowrate power consumption is 0,14 kWh for 24 hours continuous operation compared to 1,6 kWh for common ultrasonic technology (x10) and 3,6 kWh for high-pressure systems (x25).

- Very Small Footprint : Micronice system can fit in half a shoes box (15x15x15cm), and nozzles are very small and can be integrated everywhere (2cm diameter).

Tekceleo's Technology for

Humidification Systems

- Direct and Precise Control : Micronice system has a less than 10 ms latency, which means it has no inertia. It also allows for precise real time control of flowrate from 1% to 100% with 1% increment. This features makes it possible to control humidity down to the finest detail, even in the most complex spaces.

- Hygienic Operation : Micronice technology is working on running/circulating water, which reduces significantly the risk of standing water. At the same time, the system does not warm the water in any way, which reduces the risk of bacterial proliferation.

- Quiet Operation : Micronice technology operates quietly, making it suitable for use in bedrooms, offices and any areas where noise levels need to be minimized.

- Dual Effect of Cold Process Nebulization : due to the adiabatic effect the increase of humidity ensures simultaneous cooling of the air, which decrease the need for air conditioning.

- Precise and fine atomization : nebulized droplets are mono-dispersed and calibrated, with very small diameter droplets (dry fog). As a result, by choosing the right droplet size you control the time of absorption by the air.

Somes Examples of Application for Humidifying Systems

Food & Beverage Industry : humidity systems to improve shelf life of food stuff.

Printing and Paper industry : consistent paper quality in manufacturing line.

Automotive and Aerospace : effective suppression of fine dust, consistent surface tension.

Fresh products conservation and maturing: cigars humidor, cheese cave, etc.

Pharmaceutical Manufacturing environment: ensuring repeatability and fiability of chemical processes.

Electronic Industry : Prevention of static charges through constant air humidity, adiabatic cooling.

Write Us

Have questions about how Tekceleo’s humidifying systems can benefit your needs? Ready to explore customized solutions for your business?

Our team of experts is here to help. Contact us today to discuss your requirements, request a consultation, or inquire about our products and services. We’re dedicated to providing support and guidance to help you achieve your goals and develop the best products using our technologies !

Reach out to us via phone, email, or the contact form below, and let’s start working together.

Integrate the Most Efficient Humidification Technology

One of the main advantage of Tekceleo’s Micronice Technology is its energy efficiency, which is the best in the industry.

For comparison :

- Micronice technology : 6 W for 0,5L/h

- Standard Ultrasonic Humidifier : 64W for 0,5L/h

- High pressure Humidifier : 150 W for 0,5L/h

As a result, Micronice has the best energy efficiency by far. It allows for very low consumption humidification systems, even autonomous set and forget systems.

Micronice is also very efficient in terms of operation : high productivity in relation to footprint. Indeed, systems are modular and very compact (fits in 15x15x10 cm volume). Moreover, study of implementation of Micronice Nozzles have found that such systems use 60% less water than standard misting system. This is due to a more effective operation with a more precise control.

Amplified Vibrating Mesh Nozzle

Discover the innovative approach to humidification with Tekceleo’s cutting-edge Micronice technology. Unlike traditional methods such as evaporative, high-pressure, or steam, Micronice utilizes a unique piezoelectric ultrasonic approach, revolutionizing the industry. Our technology employs vibrating membranes to create calibrated droplets with high efficiency, eliminating the need for complex centralized systems or meticulous pressure and temperature controls.

Precise and Energy-Efficient Technology

Our energy efficiency sets Micronice apart, consuming merely 0.14 kWh for 24 hours of continuous operation compared to 1.6 kWh for common ultrasonic technology and a staggering 3.6 kWh for high-pressure systems.

Secondly, Micronice offers direct and precise control with less than 10 ms latency, allowing real-time adjustments from 1% to 100% flow rate with 1% increments, ensuring optimal humidity levels even in the most intricate environments. Moreover, our technology’s hygienic operation, running on circulating water without warming it, drastically reduces the risk of bacterial proliferation.

Make your Own

Controlled Environment System

Design your own controlled environment system with Tekceleo’s Micronice technology. Our modular and flexible approach allows for customized humidification solutions tailored to your specific needs. Whether you’re outfitting a small working volume, a large industrial complex, a grocery counter or a specialized laboratory, Micronice offers adaptable and reliable performance.

Using our vibrating mesh nozzles, you can establish a controlled environment that ensures comfort, productivity, and product integrity. Enjoy the benefits of precise control and efficient operation without the constraints of pre-packaged solution

Our Articles

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…