Precision Technology

for Industries that matter

Experience the power of precision technology with Tekceleo. We specialize in providing innovative solutions with advanced motion and aerosol generation technologies. Our team of experts is dedicated to helping you achieve your goals faster, more efficiently, and with greater accuracy.

Our solutions are designed to improve productivity, efficiency, and reliability, helping our clients achieve their goals faster and with greater accuracy.

Bringing motion

to the edge

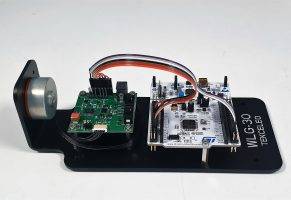

Tekceleo is committed to bringing motion technology to the edge of what’s possible. Our innovative solutions are designed to help our clients stay ahead of the competition by providing the latest advancements in motion technology and in automated aerosol generation using ultrasonic displacement.

Whether you need advanced control systems, precision positioning, or customized motion solutions, we have the expertise to help you achieve your goals. Our team is dedicated to understanding your unique needs and developing solutions that meet and exceed your expectations.

At Tekceleo, we believe that the future is bright, and we are committed to making it even brighter.

Future is not to be Expected

but to be Made Possible

Write us

Our Articles

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

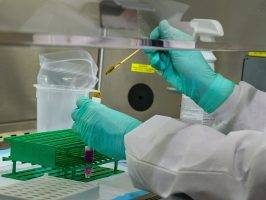

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

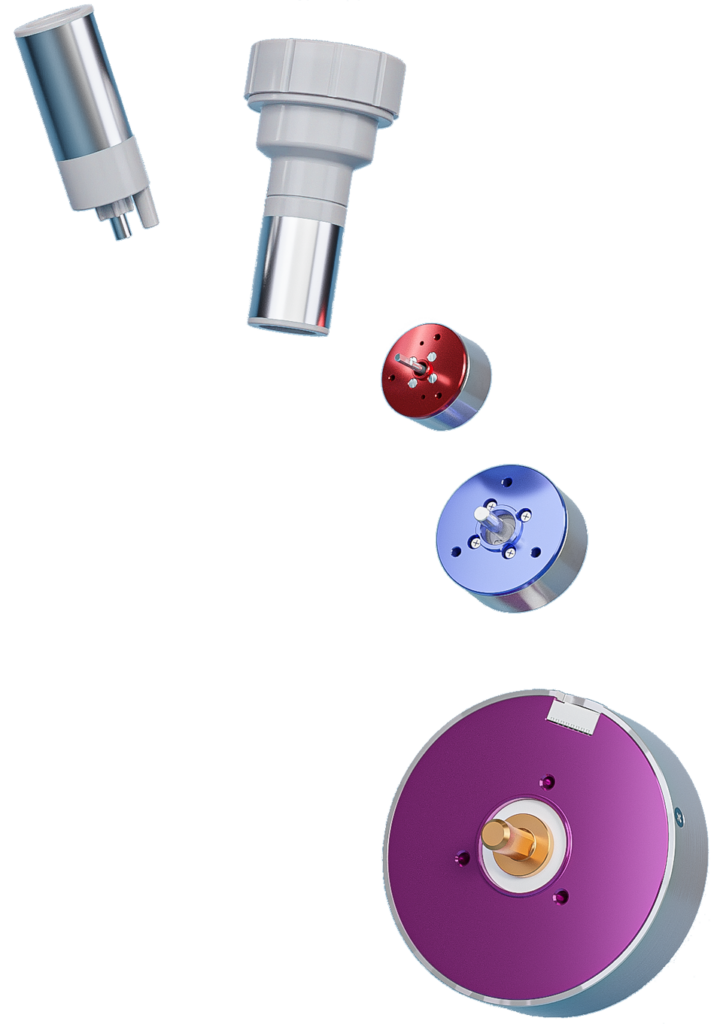

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

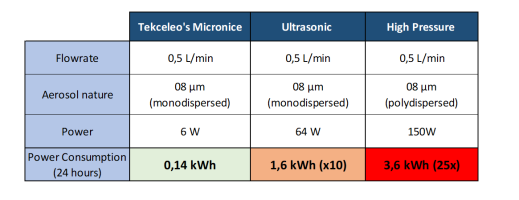

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…