Ultrasonic Motors

Tekceleo’s ultrasonic motors are the perfect solution for precise motion control in applications requiring high accuracy, high torque density, reasonable speed, and minimal noise. Our ultrasonic motors, also known as travelling wave piezoelectric motors or Wavelling© piezo motors, are capable of providing precise, miniature motion control for automation, robotics, and surgical robotics applications.

With their unique operating principles, our ultrasonic motors offer superior performance and reliability compared to conventional motors. Contact us today to learn more about how our ultrasonic motors can benefit your application.

Know more about our Non-Magnetic Piezo Motors

Tekceleo’s Piezo Motors use Wavelling ultrasonic motors technology for precise and smooth motion, making them ideal for robotics, medical devices, and automation equipment.

With a high torque-to-speed ratio and optimal precision, our Piezo Motors offer efficient and accurate movement even in tight spaces. We provide a variety of rotary motors, as well as customized solutions and technical support to seamlessly integrate our motors into your system.

Contact us to learn more about how our Piezo Motors can meet your specific needs.

Main Advantages

Our miniature motors offer precise and smooth motion, making them ideal for applications like surgical robots and injectors, where accuracy is critical. They have a high torque-low speed ratio, allowing for efficient and accurate movement even in tight spaces.

Additionally, our range of piezo motors offer the possibility to control them in Direct Drive, which eliminate the need for gears and other mechanical components. This not only simplifies your design but results in a more reliable conception.

Another advantage of ultrasonic motors is their high precision and almost no latency. They can provide very precise positioning and movement, making them ideal for use in applications that require high levels of accuracy, such as in surgical robotics, pharma processes or aerospace optronics.

At Tekceleo, we specialize in the design and manufacture of ultrasonic motors and have been at the forefront of innovation in this field for many years. Contact us if you want to know more !

Our Articles

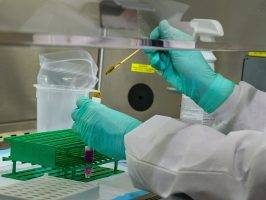

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…

In laboratory environments, it is essential to maintain high levels of contamination control to ensure the safety and accuracy of experiments. Two popular decontamination methods used in the lab are Vaporized Hydrogen Peroxide (VHP) and Hydrogen Peroxide (H2O2) nebulization. In this article,…

We are proud to announce that our ISO 9001 :2015 certification has been renewed. As a result of the audit the following strengths were noted: The new production facilities were recognized as particularly suitable and meeting the highest quality standards…

Why producing calibrated droplets for aerosol generation ? Aerosol generation is required for many applications in research, development and quality assurance. In order to provide results it is very important that the aerosol parameter is mastered and constant. By…

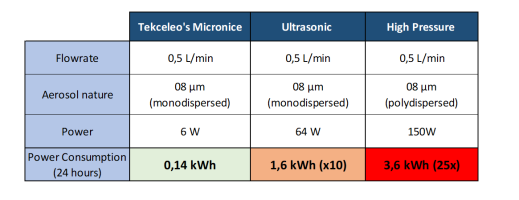

Rise of energy price seems to be a long term phenomenon that industries need to take into account. Since long, spraying, aerosol generation and misting wasn't designed in the most efficient way regarding power consumption. Indeed, historical technologies are based…

Highlights of our Ultrasonic Motors

Embedded Encoder for Precise Motion Control

Direct Drive at High torque / Low Speed

Customizable Solution

Reliable Performance

Wide range of applications

Very fast Response Time (< 1 ms)

Advanced Technical Support

Lightweight system, compact (miniature), flat or cylindrical shape

Non-Magnetic Motors

Our Wavelling Technology Overview

Travelling Wave Non-Magnetic Piezo Motors with Built-in Encoder

At Tekceleo, our Wavelling technology offers exceptional precision and control with our Travelling Wave Piezo Motors. This unique technology utilizes ultrasonic waves to create mechanical vibrations that are then converted into rotary motion. The result is smooth and precise motion control that is ideal for applications such as robotics, medical devices, and automation equipment.

Our unique WAVELLING® know-how, ranges from 20mm (for miniature motors) to 75mm diameters. The diversity of our line of motors enables them to achieve a wide range of performances and uses, ranging from nominal speeds of below 1 RPM to 600 RPM depending on the type of motors, all without a reducer (no backlash or jerks). The nominal torques can vary from a few mN.m to 2N.m depending on the type of motor.

Our Travelling Wave Piezo Motors also come with built-in encoders, providing accurate feedback on position and velocity. This feature ensures that your equipment operates precisely and reliably, with the added benefit of reduced wiring and installation time. Additionally, our motors have a high torque-to-weight ratio, making them ideal for applications where space is limited or weight is a concern.

WLG-75-R, 75 mm diameter motor

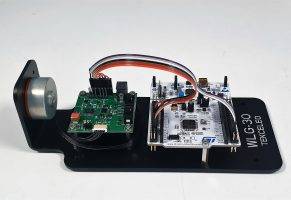

WLG-30-R, 30 mm diameter motor

WLG-20-R, 20 mm diameter motor

All of our drives incorporate speed/position sensors and can be customized depending on the application.

Examples of Applications

Miniature technology for light robotics and surgical robotics: Multi-axis robotic arms (torque control), robotic arms with force feedback (haptics), miniature robotic arms, probe positioning (MRI compatible)

Aerospace: Cubesat – Nanosatellite for space research, vacuum-resistant actuators

Optronics and Optomechanics: Alignment of optical systems, camera support (support/stabilization), laser beam control

Defense: Non-magnetic actuators for mine clearance and extreme conditions

Piezoelectric valve and mini-pump: Fast multi-channel low consumption piezoelectric valve, mini-dosing pump (pipetting, precise distribution, drop on demand, mini fluidics, etc.)

Positioning: Motorization for an XY table, hexapod, actuators for active vibration control

Technical Characteristics

Motor

Performances

Our line of piezoelectric motors ranges from 20mm to 75mm diameters.

WLG-75-R

Rated Power : 12 W / Max Torque : 1,2 N.m / Max Speed : 175 RPM

WLG-30-R

Rated Power : 1,3W / Max Torque : 100 mN.m / Max Speed : 250 RPM

WLG-20-R

Rated Power : 0,55 W / Max Torque : 30 mN.m / Max Speed : 380 RPM

Electronic Controllers

Our Electronic Controllers are using a closed loop control on speed/position.

Power Source Voltage

DC24 [V] ±0.5 [V]

Start-Stop Control

On Off digital control TTL level signal (0 or 3.3 VDC)

Start/Stopping Response

< 500 µs

Speed Setting External Voltage

DC 0[V] 〜 3.3[V]

General Characteristics

Providing cutting-edge solution, especially for non-magnetic environment.

Non-Magnetic Motors

No magnetic signature (< 3nT) / Compatible for MRI environment up to 5T

Very low weight

Ranging from 14 g to 280 g

Long lifespan

Lifespan between 30 millions to 60 millions rotations, depending on application

High Accuracy

Ranging from 0,0156° to 0,0625°, can be customized

Evaluation

Kits

Easily get started wit our Evaluation kits, including Open Softwares.

Choose your motor

From WLG-75-R to WLG-20-R / Including well-dimensioned dissipation plates

Controller and power Supply

User guide for easily getting started

STM32 Microcontroller

For easy test and evaluation

Free Demo Software

To start coding your own software